Roads, buildings, bridges, and other important constructions are all built on aggregates, which are essential components of contemporary infrastructure. These aggregates, which might be recycled materials, crushed stone, gravel, or sand, are made using a precise and methodical process. Experts in mining, civil engineering, and building must comprehend the aggregate production process. This is a summary of the fundamental steps that turn unprocessed rock into superior building materials.

Stage 1: Assessment Of The Site And Planning Of Resources

The probable location for aggregate production must be evaluated by producers prior to the start of any physical extraction. Geologists assess the terrain in order to determine the amount and quality of raw materials that are accessible. Hardness of the rock, mineral makeup, accessibility to highways, and environmental effects are important factors.

In addition to establishing a layout for the industrial plant, planning includes acquiring the required licenses and doing environmental evaluations. A well-conducted site assessment ensures regulatory compliance and maximizes production.

Stage 2: Extracting

The next step is to harvest raw materials from the ground when the location has been authorized. This usually entails surface mining methods like:

Drilling and blasting: Explosives are employed in hard rock quarries to split the rock into small, controllable pieces.

Excavation: Material is immediately removed from softer deposits, such as sand and gravel, using front-end loaders, draglines, or excavators.

The extracted material, also referred to as “shot rock” or “bank run,” is thereafter sent to the processing facility for further refining.

Stage 3: Primary Crushing

For direct application, the massive boulders that were extracted are too large. The material is broken down into smaller pieces, usually between 6 and 12 inches in size, using jaw or gyratory crushers in the first processing phase, known as primary crushing.

For big boulders to be reduced and ready for more exact processing, this step is essential. At this point, equipment selection and upkeep are crucial as efficiency affects the aggregate production process’s overall performance.

Stage 4: Secondary and Tertiary Crushing

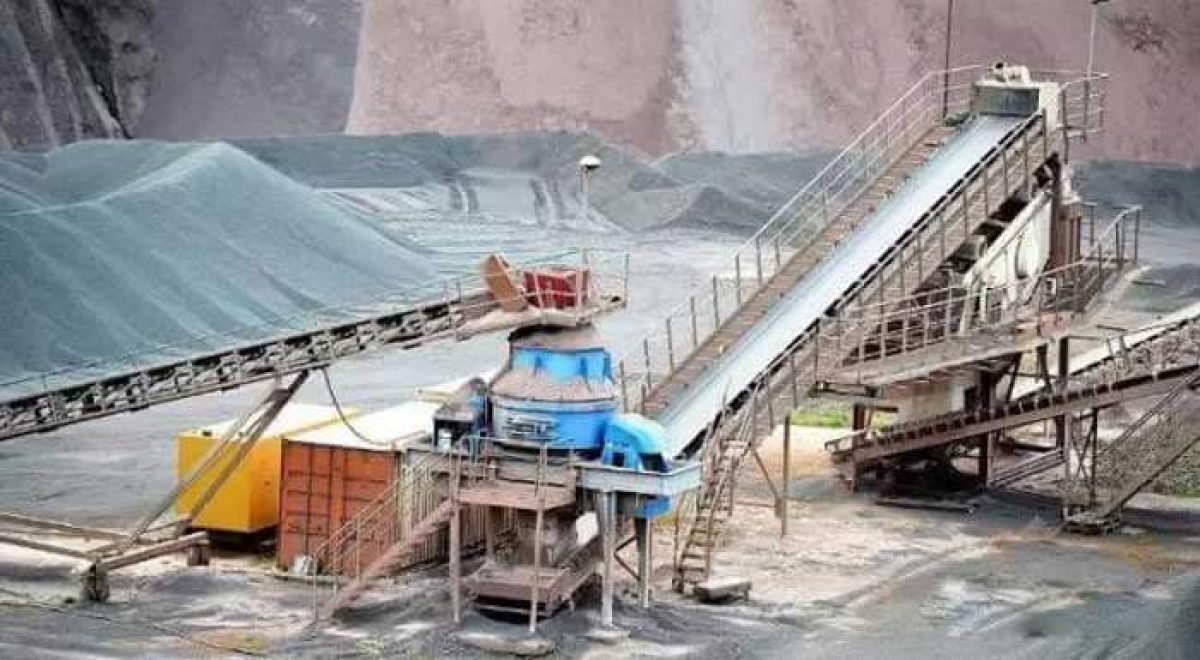

Following the first crushing, secondary and sometimes tertiary crushers are used to process the material. The aggregate’s size and form are further refined by these devices, which include hammer mills, impact crushers, and cone crushers.

Depending on the material’s intended purpose (e.g., foundation material, asphalt, or concrete), each crushing step makes sure the material satisfies size criteria. Producing a consistent, superior product with fewer fines (dust or powder) is the aim.

Stage 5: Evaluation and Dimensioning

The screening stage comes after the aggregate has been crushed. Using mesh holes, vibrating screens divide the material into various size fractions. Common sizes consist of:

- Sand-like fine aggregates

- Grains or medium aggregates

- Coarse stone aggregates

Materials that are the right size are sent to storage, while larger particles are sent back to the crushers for further processing. By taking this step, uniformity and adherence to industry standards for grading are guaranteed.

Stage 6: Cleaning and Sorting

Washing aggregates to get rid of clay, silt, and other contaminants may be necessary, depending on the source material and its intended application. Especially in applications involving concrete and asphalt, washing improves the finished product’s performance and cleanliness.

Equipment for classifying materials by density or particle size includes sand screws and hydrocyclones. As a result, specialist materials like manufactured sand and concrete-grade stone are produced.

Stage 7: Storage and Stockpiling

The aggregates are transported to certain stockpiles, each of which is divided by size and kind, after processing. In order to avoid material contamination, segregation, and deterioration, proper stockpile management is essential. To ensure consistency, common practices include layered dumping procedures and radial stacking conveyors.

In order to ensure the aggregate satisfies requirements, producers often use quality control procedures at this point, such as sampling and testing.

Phase 8: Transport and Loading

In order to transport the completed materials to building sites or distribution hubs, the aggregate production process culminates with loading them into trucks, barges, or railcars. In addition to lowering transportation expenses, effective load management and logistics guarantee on-time client delivery.

In Conclusion

The aggregate production process is a multi-stage extraction, crushing, sizing, and quality control operation that is intricate and well-planned, from geological reconnaissance to final delivery. The foundation of infrastructure across the globe is made up of durable, dependable, and reasonably priced building components that are produced at each stage.

In addition to demonstrating the technical complexity of aggregate production, an understanding of these phases reaffirms their significance in promoting both economic growth and sustainable development. As the market for premium aggregates keeps growing, advancements in environmental and processing techniques will be increasingly more crucial in determining the direction of the sector.